Polybutadiene Rubber

UBE Elastomer’s synthetic rubber business manufactures and sells butadiene rubber (BR) which is one of the typical synthetic rubber. Our BR is said to be high-cis BR synthesized by cobalt catalyst system. Our company has production sites in Japan, Thailand, and China.

1. Characteristics of process

Our processing technology enables us to easily control the BR’s molecular weight, branching degree of molecular chains, and molecular weight distribution.

Furthermore, our technology realizes combining BR with high-crystalline syndiotactic polybutadiene (SPB) resin.

2.Characteristics of products

UBEPOL BR® (high-cis BR)

UBEPOL BR® meets a wide variety of customer demand, including the grades with sperior physical properties such as abrasion resistance, rebound, heat buildup, and crack growth resistance and the grades with excellent processing characteristics such as mixing with various fillers, extrudability, and roll banding.

UBEPOL VCR® (composite of rubber and resin)

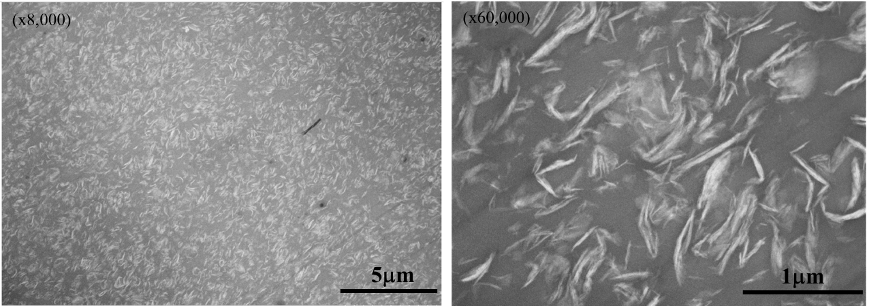

UBEPOL VCR® is the grade that combines BR and high-crystalline syndiotactic polybutadiene (SPB) resin. SPB resin is well dispersed in BR matrix (Figure: TEM images). UBEPOL VCR®, having characteristic polymer alloy structure, can contribute to improve hardness, elastic modulus, crack growth resistance, and extrusion characteristics (extrusion output and dimensional stability) and weight reduction/thinning of rubber products.

Characteristics of UBEPOL BR® and UBEPOL VCR® for rubber uses

| Product Name | Mooney viscosity (ML1+4、100℃) |

Characteristics | |

|---|---|---|---|

| UBEPOL BR® | 150 | 43 | Standard grade of UBEPOL BR®; superior balance of processability and various physical properties |

| 130B | 26 | Low Mooney viscosity grade of BR150B; best processability and suitable for high filler loading | |

| 150B | 37 | Branching of BR150; superior processability | |

| 360B | 47 | High Mooney viscosity grade of BR150B; superior abrasion resistance and processability | |

| 150L | 43 | Low branching grade of BR150; superior abrasion resistance, rebound, and heat buildup | |

| 360L | 47 | High Mooney viscosity grade of BR150L; superior abrasion resistance, rebound, and heat buildup | |

| 230 | 35 | Grade with bimodal molecular weight distribution; superior roll processability and extrusion characteristics | |

| 133P | 32 | Non-staining oil extended grade that includes 37.5 phr of highly safe paraffin oil | |

| UBEPOL VCR® | 412 | 45 | Standard grade of UBEPOL VCR®; superior extrusion characteristics, easily enhance hardness and elastic modulus |

| 617 | 62 | Grade with higher SPB resin content than VCR412; easily enhance hardness, elastic modulus | |

| 450 | 36 | Grade with BR matrix of broad molecular weight distribution; good balance between VCR characteristics and general BR physical properties | |

| 800 | 37 | Grade with BR matrix of broad molecular weight distribution and higher SPB crystal content than VCR450 | |

Characteristics of UBEPOL BR® for modified resi application (HIPS)

| Product Name | Mooney viscosity (ML1+4、100℃) |

5% styrenesolution viscosity(cps) | Characteristics | |

|---|---|---|---|---|

| UBEPOL BR® | 15HB | 37 | 60 | High-cis BR for modified resin (HIPS); superior impact resistance |

3.Applications

- Various tires, including for passenger vehicles, trucks/buses, construction vehicles, two-wheeled vehicles and bicycles

- Various industrial products, including polystyrene modifiers, conveyor belts, hoses, anti-vibration rubber, and casters

- Commodities, including shoe soles and golf balls